Comprehensive Guide to Hydraulic Systems & Hydraulic Cylinders: Components, Types, and Applications

Description

A machine is essentially a complex hydraulic system. The function of a hydraulic system is to increase the force by changing the pressure. A complete hydraulic system is composed of five parts: power components, actuators, control components, auxiliary components (accessories), and hydraulic oil.

Power Components

The role of power components is to convert the mechanical energy of the prime mover into the pressure energy of the fluid. This refers to the hydraulic pump in the hydraulic system, which provides power to the entire system. Common types of hydraulic pumps include gear pumps, vane pumps, and piston pumps.

Actuators

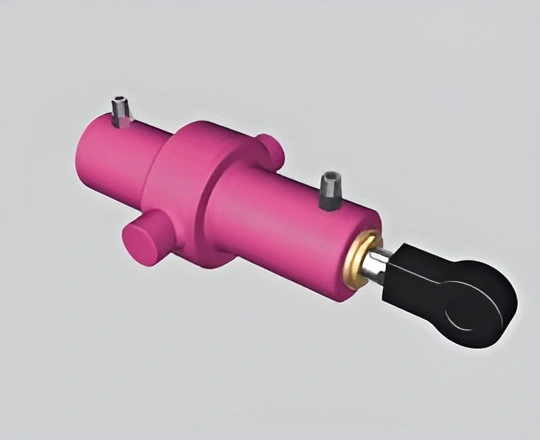

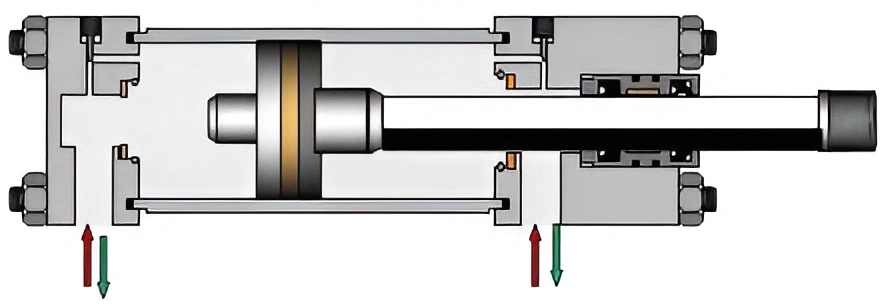

Actuators (such as hydraulic cylinders and hydraulic motors) convert the pressure energy of the fluid into mechanical energy to drive a load in linear reciprocating or rotary motion.

Control Components

Control components (i.e., various hydraulic valves) are used in the hydraulic system to control and regulate the pressure, flow, and direction of the fluid.

Auxiliary Components

Auxiliary components include oil tanks, filters, oil pipes and fittings, sealing rings, quick couplings, high-pressure ball valves, hose assemblies, pressure testing joints, pressure gauges, oil level gauges, oil thermometers, etc.

Hydraulic Oil

Hydraulic oil is the working medium used to transmit energy in the hydraulic system. It includes various types such as mineral oil, emulsions, and synthetic hydraulic oils. In China, No. 46 anti-wear hydraulic oil is generally used for hydraulic cylinders.

Hydraulic Cylinder Types & Configurations

By Function:

Single-acting Cylinders: Force in one direction, spring/gravity return.

Double-acting Cylinders: Bidirectional force for precision control.

By Structure:

Telescopic/Multi-stage Cylinders: Extended reach with compact retraction.

Plunger/Ram Cylinders: Heavy-duty unidirectional force (ideal for presses).

Differential Cylinders: Optimized for rapid cycle times.

Pressure Ratings: 16MPa, 25MPa, 31.5MPa options for diverse workloads.

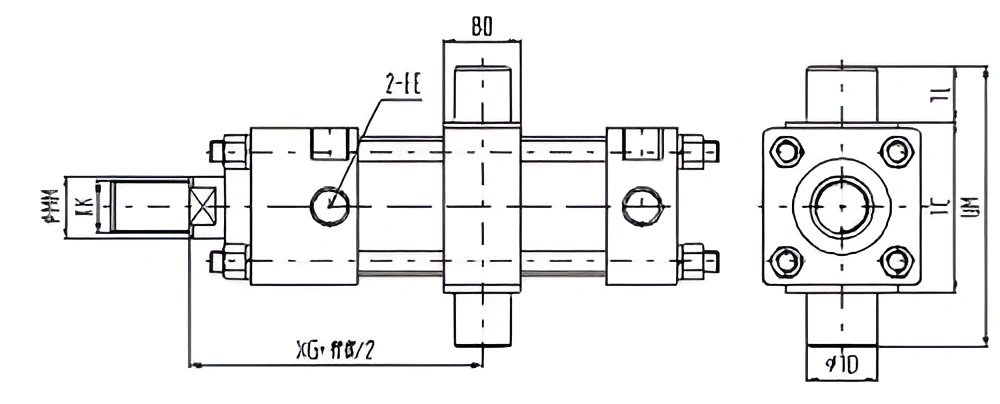

Mounting Styles: Clevis, flange, foot, or trunnion mounts for flexible integration.

Hydraulic Cylinder Construction

Crafted for durability, cylinders feature:

Barrel & End Caps: Welded or tie-rod designs (20# steel).

Piston & Rod Assembly: Stainless steel or carbon steel for corrosion resistance.

Sealing Solutions: Premium seals (Parker, Merkel, Trelleborg) prevent leaks.

Guiding Systems: Precision-machined bushings ensure smooth operation.

Industrial Applications

From excavators and cranes (telescopic cylinders) to injection molding machines (double-acting cylinders), hydraulic systems drive performance in:

Construction & Mining

Manufacturing & Metalworking

Marine & Aerospace