Hydraulic Cylinder Repair

Repairing a hydraulic cylinder is a critical maintenance task for ensuring the reliability and performance of hydraulic systems in machinery such as excavators, forklifts, presses, and agricultural equipment.

At JW HYDRAULIC, we power your machinery with innovation and expertise, delivering end-to-end hydraulic cylinder solutions—from precision-engineered new builds to expert repairs. Whether you’re upgrading or revitalizing, we ensure your equipment operates at peak performance!

How to rebuild a hydraulic cylinder ?

Common Signs a Cylinder Needs Repair

- Fluid leakage (external or internal).

- Slow or erratic movement (uneven extension/retraction).

- Loss of power or inability to hold loads.

- Visible damage (bent rod, scored barrel, or dented housing).

- Contaminated hydraulic fluid (metal shavings or debris in the oil).

Safety Precautions

- Depressurize the system before disassembly.

- Wear protective gear (gloves, goggles) to avoid injury from hydraulic fluid or springs.

- Secure the cylinder in a vise or clamp to prevent movement during repair.

Tools and Materials Needed

- Basic tools: Wrenches, screwdrivers, pliers, rubber mallet.

- Specialized tools: Seal pullers, piston rod vise, hydraulic press.

- Replacement parts: Seal kit (O-rings, wipers, gland seals), new piston rod or barrel (if damaged).

- Cleaning supplies: Solvent, lint-free cloths, compressed air.

- Lubricant: Hydraulic oil or assembly grease.

Step-by-Step Repair Process

Disassembly

- Remove the cylinder from the equipment.

- Drain hydraulic fluid into a container.

- Detach end caps/gland nuts using appropriate tools.

- Extract the piston rod assembly carefully to avoid damaging seals.

- Remove the piston from the rod (if applicable).

Inspection

- Check the piston rod: Look for bends, scratches, or pitting (use a micrometer for precision).

- Inspect the barrel (cylinder tube): Ensure it’s smooth and free of scoring or corrosion.

- Examine seals and wipers: Replace all worn or cracked seals.

- Assess the piston: Check for wear or damage to the piston head and threads.

Cleaning

- Clean all components with solvent and compressed air.

- Avoid abrasive materials that could scratch surfaces.

Reassembly

- Lubricate new seals with hydraulic oil before installation.

- Reinstall the piston onto the rod (ensure proper torque if using bolts).

- Slide the piston rod assembly back into the barrel.

- Reattach end caps/gland nuts with a torque wrench (follow manufacturer specs).

- Replace hydraulic fluid and bleed air from the system.

Cleaning

- Clean all components with solvent and compressed air.

- Avoid abrasive materials that could scratch surfaces.

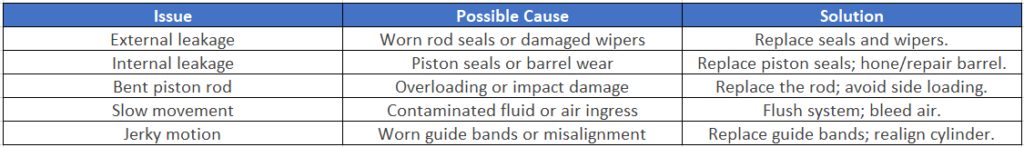

Common Problems and Solutions

When to Seek Professional Help

- Severe barrel/piston damage: Requires machining or replacement.

- Complex systems (e.g., telescopic cylinders, servo cylinders).

- Lack of specialized tools (e.g., hydraulic press for straightening rods).

Preventive Maintenance Tips

- Regularly check fluid levels and quality.

- Inspect seals and rods for wear during routine maintenance.

- Keep cylinders clean to prevent contamination.

- Avoid overloading or misaligning the cylinder.

Cost Considerations

- DIY repair: 50–50–300 (seal kits and basic tools).

- Professional repair: 500–500–2,000+ (depending on cylinder size and damage).

By following these steps, you can extend the lifespan of hydraulic cylinders and maintain the efficiency of your equipment.