Key Technical Parameters in Hydraulic Cylinder Design

A Comprehensive Guide

Hydraulic cylinders are critical components in machinery across industries, from construction to manufacturing. Their performance hinges on precise design and engineering. Understanding the key technical parameters ensures optimal functionality, durability, and safety. This guide explores the essential design considerations and performance metrics that define a high-quality hydraulic cylinder.

1. Core Design Parameters of Hydraulic Cylinders

1.1 Cylinder Bore Diameter

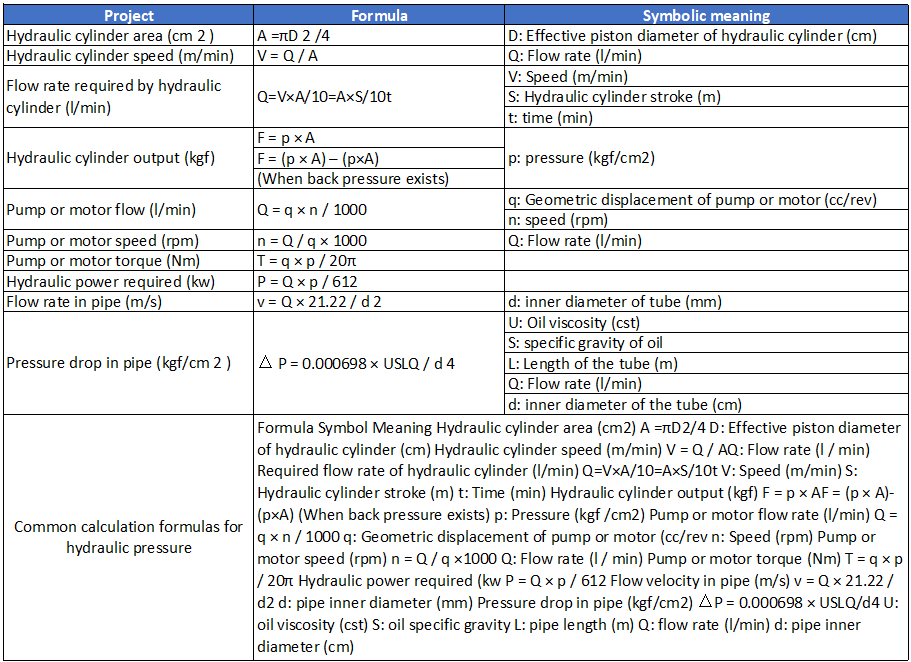

The cylinder’s inner diameter (ID) directly impacts its force output. Calculated using the formula F = P × A (where F = thrust force, P = working pressure, and A = piston area), the bore diameter determines the cylinder’s load capacity. A larger bore increases force but requires higher fluid volume.

1.2 Port Size and Thread Specifications

Inlet/outlet port diameters and thread types (e.g., metric, UNF, or BSPP) must align with system pressure and flow rates. Proper sizing minimizes pressure drops and ensures efficient fluid transfer.

1.3 Piston Rod Diameter

Piston rod diameter is selected based on load conditions (compression/tension). Thicker rods enhance stability under heavy loads, while thinner rods suit compact designs. Reference tables (e.g., ISO standards) guide diameter selection.

1.4 Working Pressure and Test Pressure

- Working Pressure: The operational pressure range (e.g., 10–25 MPa).

- Test Pressure: Safety validation pressure (≤16 MPa: 1.5× working pressure; >16 MPa: 1.25×).

1.5 Stroke Length

The maximum extension/retraction distance of the piston rod. Stroke length depends on application needs, such as lifting height or machine reach.

1.6 Buffering Mechanism

Cylinders exposed to high-speed movements or heavy loads require integrated buffering to absorb shock, prevent piston impact, and extend component life.

1.7 Mounting Configuration

Mounting styles (e.g., flange, clevis, or trunnion) affect alignment, load distribution, and ease of installation.

2. Performance Metrics for Hydraulic Cylinder Quality

2.1 Minimum Starting Pressure

The lowest pressure required to initiate piston movement (no-load condition). Reflects manufacturing precision and seal friction efficiency. Lower values indicate superior quality.

2.2 Minimum Stable Speed

The slowest speed at which the piston moves smoothly without crawling (jerky motion). Critical for precision applications like CNC machinery.

2.3 Internal Leakage

Leakage between piston and bore reduces volumetric efficiency, causes overheating, and compromises positioning accuracy. High-performance seals minimize leakage.

3. Structural Design Considerations

3.1 Cylinder Dimensions

- Cylinder Length: Calculated as Stroke + Piston Length + Guide Length + Seal Length + Buffer Length.

- Piston length: (0.6–1)× bore diameter.

- Guide length: (0.6–1.5)× piston rod diameter.

3.2 Radial Seal Groove Design

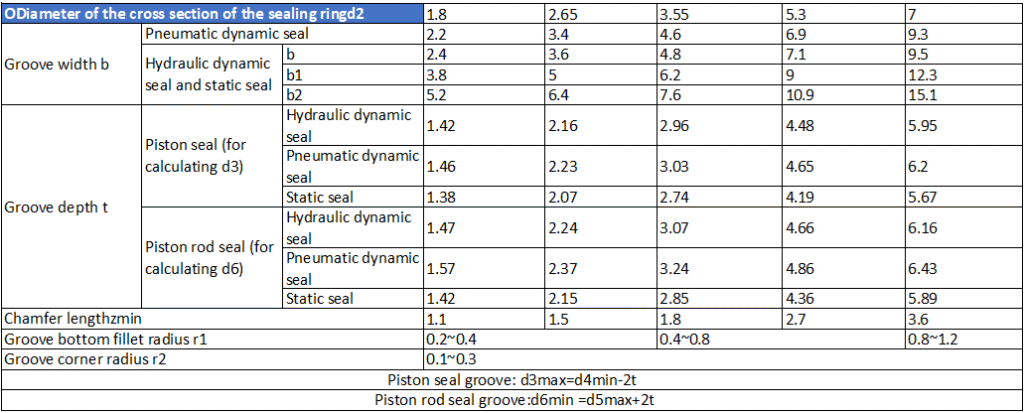

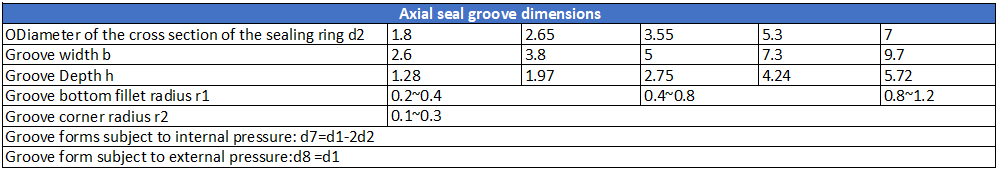

- O-Ring Grooves: Dimensions (d1–d10) and surface roughness (Ra ≤0.4 μm) ensure leak-free operation.

- Clearance (2g): Radial gap between components to prevent seal extrusion.

3.3 Thread and Fastener Standards

- Bolt Load Capacity: Metric/coarse threads (per GB3098.1-82) require precise torque values (e.g., Rexroth servo cylinders).

- Material Strength: Bolts must meet tensile/yield strength grades (e.g., 8.8, 10.9) with controlled surface hardness.

4. Material and Seal Selection

- Piston Seals: Combination seals (e.g., PTFE + elastomer) balance low friction and high wear resistance.

- Rod Seals: Multi-lip designs prevent contamination ingress.

- Wear Rings: Guide bands reduce metal-to-metal contact, extending cylinder life.

What Defines a Reliable Hydraulic Cylinder?

A high-quality hydraulic cylinder isn’t just about meeting dimensions—it’s about excelling in performance metrics like low leakage, smooth operation, and robust construction. By prioritizing precision in design, material selection, and testing, manufacturers ensure cylinders withstand demanding applications while minimizing downtime.

For industries seeking longevity and efficiency, partnering with suppliers who adhere to international standards (ISO, GB) is non-negotiable. Explore our range of certified hydraulic solutions designed to power your machinery flawlessly.